Characteristics of the cleanroom project:

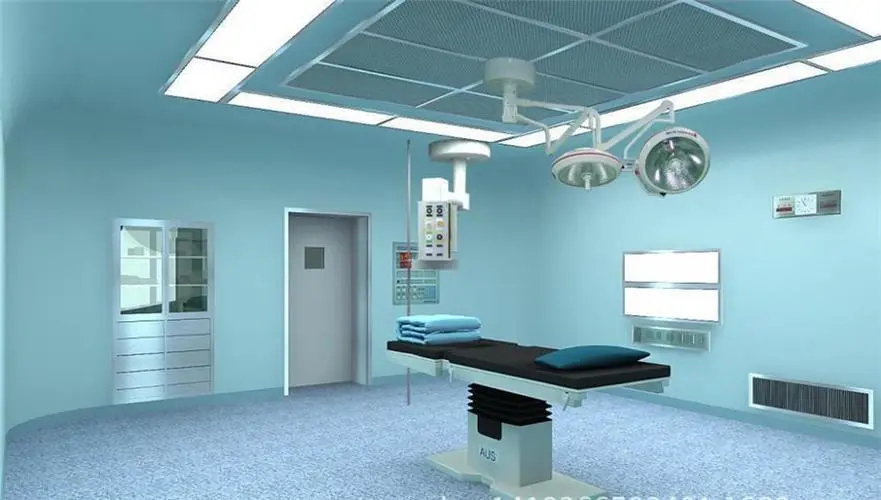

Applicable to clean operating room, 10,000 purification project, 100,000 purification project, clean workshop

Purification principle: air flow –> primary purification –> purification air conditioning –> intermediate purification –> fan Air supply–>Piping–>High-efficiency purification air outlet–>Blowing into the room–>Take away the dust, bacteria and other particles–>return air shutters–>primary purification repeat the above process, you can achieve the purpose of purification.

With the modern hospital conditions, environment and quality of medical care continue to improve and enhance, laminar flow equipment has been gradually equipped, applied to the operating room. The following is the introduction of the laminar flow operating room purification project.

Laminar flow operating room is the use of air clean technology to take different degrees of microbial contamination control, to achieve the control of air cleanliness in the spatial environment suitable for various types of surgical requirements; and to provide the appropriate temperature, humidity, to create a clean and comfortable surgical space environment. Since the operating room should strictly control the low bacterial count and low anesthetic gas concentration, the stability of the laminar flow ultra-clean device is an important acceptance index of the laminar flow purification operating room. Due to the subtle differences between the European and American operating room cleanliness standards and the Chinese environment, conventional international standards and domestic regional industry standards are generally difficult to ensure the long-term stability of the operating room purification (generally only 3-10 years to rebuild, low-grade projects need to be refurbished in 1 year), so the quality of the project appeared to be a clear division of the grades. OUDELONG is committed to achieving more than the international standards of purification indexes.

1、Clean flow operating room – clean and comfortable working environment

Laminar flow operating room is the use of air clean technology to take different degrees of microbial contamination control, to achieve the control of air cleanliness in the spatial environment suitable for various types of surgical requirements; and to provide the appropriate temperature, humidity, to create a clean and comfortable surgical space environment.

Laminar flow operating room not only requires a high degree of clean air (air entering the operating room must first be purified by a high-efficiency filter), but also requires the ability to control the direction of air flow (i.e., the use of laminar flow ultra-clean device), so that the air flow from the high cleanliness of the surgical area to the low cleanliness of the region, and to take away and discharge dust particles (dust particles) and bacteria in the air flow; laminar flow is a fine, thin layer of the air flow to an even flow rate to the same direction. Laminar flow is a small, thin layer of airflow that is transported in the same direction at a uniform flow rate; the direction of the purified airflow is divided into two types: vertical laminar flow and horizontal laminar flow. Vertical laminar high-efficiency filters are installed on the wall on the side of the foot of the patient, the airflow is blown horizontally, and the return air outlet is located on the ceiling near the wall on the opposite side. Generally more vertical laminar flow type effect is better.

Laminar flow operating room is a “positive pressure” environment, the air pressure according to its different areas (such as operating room, sterile preparation room, restroom, anesthesia room and around the clean area, etc.) cleanliness of different requirements and different.

Different levels of laminar flow system, the air replacement rate in the controlled space environment is also different, the higher the cleanliness level, the faster the replacement rate, and vice versa.

The walls of the laminar flow operating room are painted with special paint that has antibacterial effect, bright light, soft color and do not need to be cleaned and rinsed with water.

2. Functional characteristics of purified laminar flow operating room

2.1 Low bacterial count and low anesthetic gas concentration in the operating room.

2.2 Comfortable airflow available (room temperature can be adjusted between 15-25℃ and humidity between 50-65%).

2.3 Positive airflow in the operating room (+23-25 Pa) prevents the entry of foreign contamination.

2.4 The air in the operating room is fresh and clean, and the working environment is comfortable.

2.5 Laminar flow operating room, in general, does not need to use physical or chemical methods of disinfection, both labor-saving, but also exempted from the adverse air effects.

2.6 The rate of nosocomial infection (especially the rate of surgical and burn infection) is greatly reduced.

3、Management of laminar flow operating room environment

Laminar flow system is to create a clean operating room equipment, no matter how advanced it is, but it is not omnipotent; so the laminar flow system does not have the efficacy of sterilization, laminar flow operating room “aseptic” environment is mainly through the air “filtration”, “laminar flow” as well as the indoor maintenance of the “positive pressure” state to maintain.

Therefore, the management of laminar flow operating room environment must be emphasized:

(1) Entering the operating room must change hand-washing clothes, shoes and hats.

(2) Strictly control the number of people entering the room.

(3) Minimize the number of times and time to open the door of the laminar flow operating room (not to mention the door can not be opened and not closed), to maintain a “relatively airtight state” to prevent the entry of foreign pollution.

(4) Use alcohol to wipe indoor objects, medical instruments, equipment, etc. before surgery.

(5) After the surgery, clean all items, walls and floors of the room promptly and thoroughly.

(6) Women are not allowed to use cosmetics such as hair sprays and nail polish to minimize sources of contamination.

(7) Work clothes should be made of polyester and nylon fabrics that are not easy to produce static electricity and shed fibers.