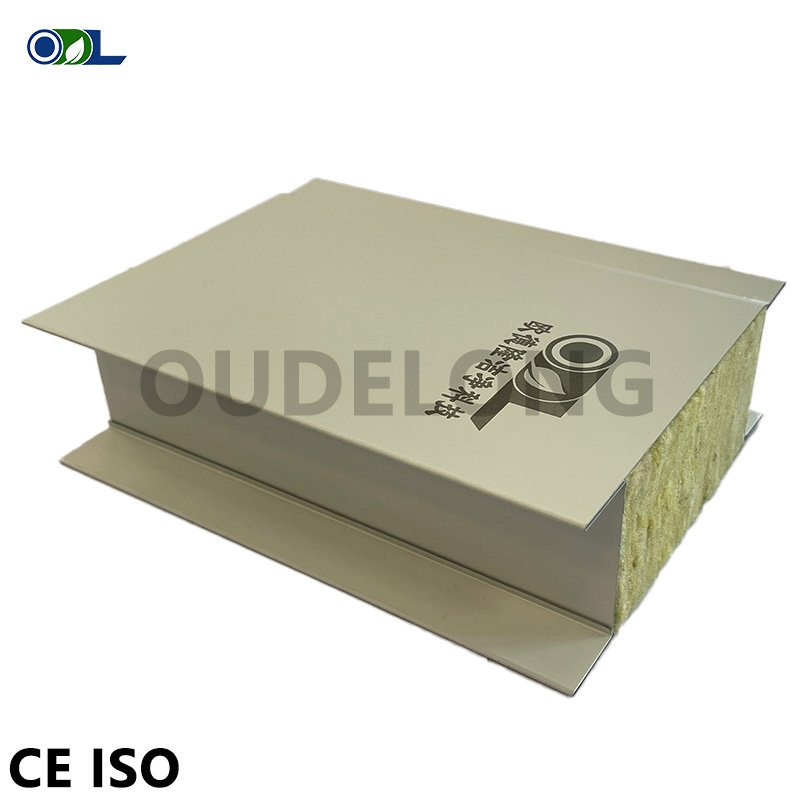

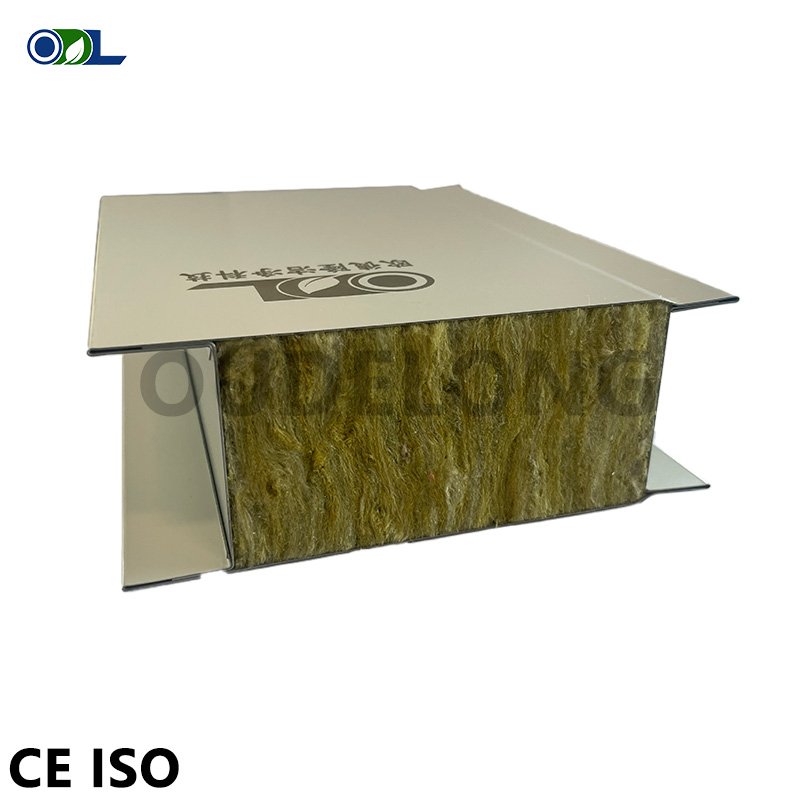

The rock wool sandwich color steel plate ( Rockwool sandwich panel )is a kind of building material with excellent performance, which is composed of two layers of color steel plates and the rock wool core material in the middle. The following is a detailed introduction to the product:

Rockwool sandwich panel Product Characteristics

- Outstanding Fire Resistance: The rock wool core material is a Class A non-combustible material, which can effectively prevent the spread of fire and provide reliable fire protection for buildings

- Good Thermal Insulation Performance: The fiber structure of rock wool makes it have a low thermal conductivity, which can reduce the heat exchange between indoor and outdoor and reduce energy consumption

- Sound Insulation and Noise Reduction: Its unique structure can effectively absorb and block the transmission of sound, creating a quiet and comfortable environment indoors

- High Strength and Stability: The combination of color steel plates and rock wool core material makes the plate have high compressive and flexural strength, ensuring the structural stability of the building

- Corrosion Resistance: The surface of the color steel plate is specially treated and has good corrosion resistance, which can adapt to various harsh environments

| Technical Parameter | |

| Thickness | 50mm, 75mm, 100mm, 150mm, 200mm |

| Standard width | 950mm, 1150mm |

| Tolerance | ≤1mm |

| Maximum Length | ≤10000mm |

| Panel Coating Material | PE, can be customised with PVDF, anti-static, stainless steel, HDP and PVC coatings. |

| Filled Core Material | Rock wool (Density: 100~120 kg/m³) |

| Panel thickness | 0.45mm, 0.5mm thickness available |

| Protective coating | 0.06mm thickness, >0.06mm can be customised |

| Connection method | Flange type |

| Fireproof | yes |

| Type | H-board (flat, pressed), stand-up board, corrugated sandwich panel |

Production Process

During the production process, the color steel plate is pretreated first, and then the rock wool core material is laid between the two layers of color steel plates, and is pressed and bonded through automatic equipment to ensure the firm combination of the plate

Application Field

Rock wool sandwich color steel plates are widely used in industrial plants, warehouses, cold storage, movable panel houses, purification workshops and other construction fields to meet the requirements of different places for fire protection, thermal insulation, sound insulation, etc

In conclusion, the rock wool sandwich color steel plate is a widely used building material with excellent performance in various aspects, providing reliable solutions for different construction needs.

Reviews

There are no reviews yet.