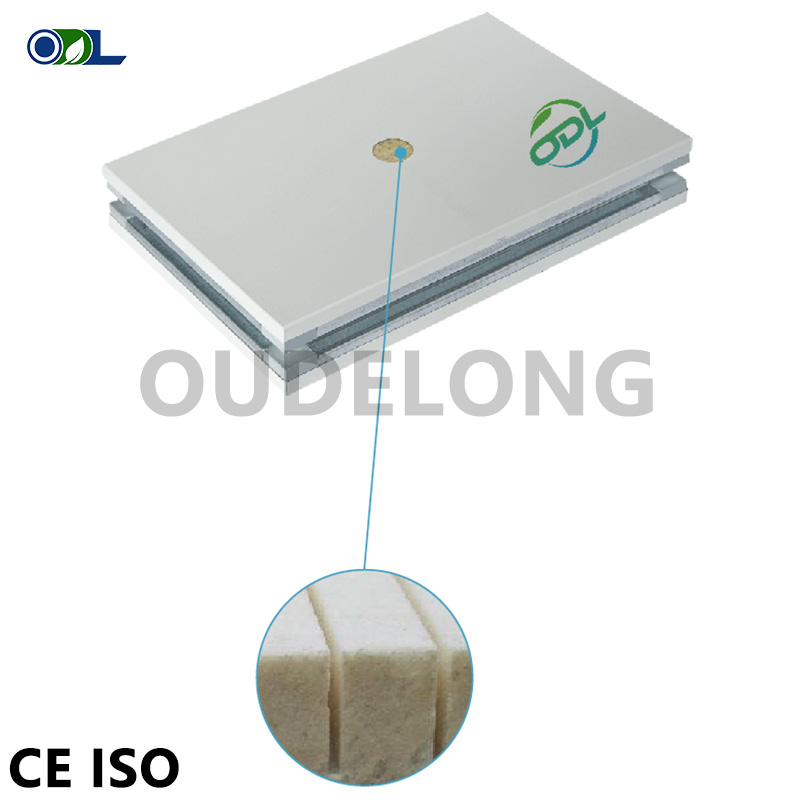

Polyurethane (PU) manual clean plates(PU sandwich panel), also known as polyurethane insulated composite panels, are a type of building insulation panel that utilizes polyurethane rigid foam as the insulating layer between two layers of colored steel sheets, single-layer steel sheets, stainless steel, etc., through manual process composite purification board, because it has the effect of dust-proof, anti-static, antibacterial, etc., is widely used in electronics, food, biology, coating, instrument manufacturing and other harsh requirements of the indoor environment Purification engineering field.

The product description is as follows:

PU sandwich panel Product Characteristics

- Superior Insulation Performance: The PU manual clean plates have a low thermal conductivity, with small heat transfer coefficients and excellent thermal insulation properties, making them one of the best insulation materials available

- Attractive Panel Design: The PU manual clean plates have an aesthetically pleasing appearance, easy to install, and a seamless and visually appealing finish that combines load-bearing, insulation, fire resistance, and water resistance

- Good Fire Resistance: The product achieves a B1 fire rating, meaning it can self-extinguish in case of small fires, featuring robust heat-resistant materials and high bending strength

- Eco-Friendly and Non-Toxic: The PU manual clean plates are free from toxic substances and odors, and can withstand a wide range of temperatures, suitable for use in various environmental conditions

- High Tensile Strength: The PU manual clean plates have high tensile strength and good flexibility, allowing them to be used in a variety of construction projects

| Technical Parameter | |

| Thickness | 50mm, 75mm, 100mm, 150mm, 200mm |

| Standard width | 950mm, 1150mm |

| Tolerance | ≤1mm |

| Maximum Length | ≤10000mm |

| Panel Coating Material | PE, customised with PVDF, anti-static, stainless steel, HDP and PVC coatings. |

| Filled Core Material | Polyurethane Weight 40kg/m³-45kg/m³ |

| Panel thickness | 0.45mm, 0.5mm thickness available |

| Thickness of keel | 0.6mm-0.8mm |

| Corner | Galvanised/ABS |

| Bending ability | 0.9KN/m² |

| Bonding performance | 0.15MPa |

| Peeling rate | ≥ 85%-≤ 98%. |

| Heat transfer coefficient | ≤0.030 m.k |

| Protective Coating | 0.06mm thickness, >0.06mm can be customised |

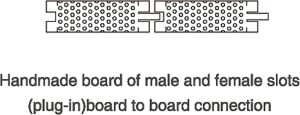

| Connection method | Middle aluminium connection , male and female port continuous type |

| Fireproof | yes |

| Type | H-board (flat, pressed), enterprise mouth board, corrugated sandwich panel |

Production Process

During the production process of PU manual clean plates, advanced six-component online automatic mixing casting technology and full-automatic cotton system are adopted to complete the mixing ratio online once, and the temperature can be adjusted automatically online to produce high-strength, energy-efficient, green environmental protection, soundproof and fireproof materials

Application Field

Due to its excellent comprehensive benefits and cost-performance ratio, PU manual clean plates are widely used in industrial factories, logistics warehouses, integrated houses, etc., and is a widely used and promising high-efficiency energy-saving building enclosure material

In summary, PU manual clean plates is a high-quality insulation material with a combination of excellent thermal insulation, fire resistance, and environmental friendliness, making it a popular choice for modern construction projects.

Reviews

There are no reviews yet.