Magnesium Manual Board, also known as magnesium clean board or magnesium partition board, is a new type of indoor partition board mainly made of magnesium plate as the core material, which has the advantages of good fire resistance and water resistance, and is mainly used for indoor fire separation in buildings

The product description is as follows:

Product Characteristics

- Environmental Protection: Magnesium manual clean board is a green environmental protection product, which does not produce harmful gases and waste in the production process, is harmless to the human body, and has a good environmental performance

- High Fire Resistance: As non-flammable A-class materials, the boards have good fire resistance and can effectively block the spread of fire to ensure building safety

- Waterproof and Moisture-Proof: The board has excellent waterproof and moisture-proof performance, and can maintain stability even in humid environments, without deformation or mold growth

- Easy to Install: Due to its light weight and high strength, magnesium manual clean board is easy to handle and install, with high construction efficiency, which can greatly shorten the construction period

- Antibacterial and Dust-Proof: The surface of the board has been specially treated, with excellent antibacterial and dust-proof effects, which can effectively inhibit bacterial growth and keep the indoor air fresh

| Technical Parameter | |

| Thickness | 50mm, 75mm, 100mm, 150mm, 200mm |

| Standard width | 950mm, 1150mm |

| Tolerance | ≤1mm |

| Maximum Length | ≤10000mm |

| Panel Coating Material | PE, customised with PVDF, anti-static, stainless steel, HDP and PVC coatings |

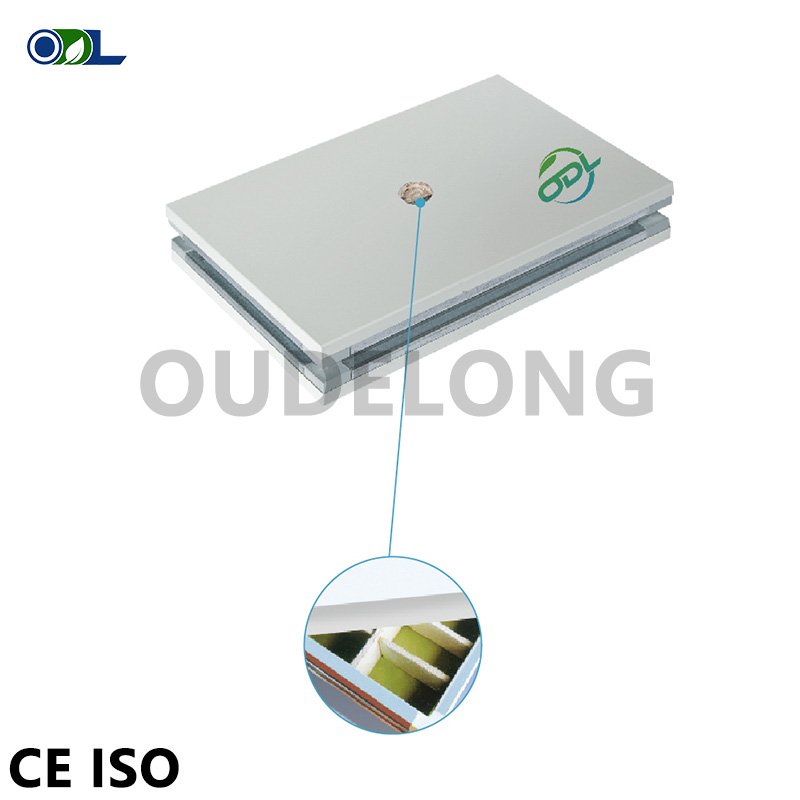

| Filled Core Material | Magnesium thickness 5mm |

| Panel thickness | 0.45mm, 0.5mm Thickness Available |

| Thickness of keel | 0.6mm-0.8mm |

| Corner | Galvanised/ABS |

| Bending ability | 0.9KN/m² |

| Bonding performance | 0.15MPa |

| Peeling rate | ≥ 85%-≤ 98%. |

| Heat transfer coefficient | 0.73W/m²-K |

| Protective Coating | 0.06mm thickness, >0.06mm can be customised |

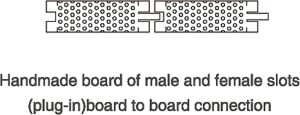

| Connection method | Middle aluminium connection , male and female port continuous type |

| Fireproof | Yes |

| Type | H-board (flat, pressed), flat board, corrugated sandwich panel |

Production Process

In the production process of magnesium manual clean board, high quality magnesia and magnesium chloride are selected as raw materials, then the necessary auxiliary materials and water are mixed to form a uniform slurry. Then the slurry is poured into the mold for forming, and finally goes through natural curing and drying treatment to obtain the final sheet material products

Application Field

Due to its excellent performance, magnesium manual clean board is widely used in electronic, pharmaceutical, food, biological, aerospace, precision instrument manufacturing and other high-demand netting engineering fields

In Conclusion

In conclusion, magnesium manual clean board is a high-performance building material with a combination of excellent fire resistance, water resistance, environmental protection, and easy installation, making it a popular choice for high-standard clean room projects.

Reviews

There are no reviews yet.